+ years of excellence and the story has just begun.

Delivering world-class engineering solutions from design to turnkey execution powered by innovation, precision, and the most capable engineering teams in Turkey.

10

10

ALL REFERENCES

+ years of excellence and the story has just begun.

Delivering world-class engineering solutions from design to turnkey execution powered by innovation, precision, and the most capable engineering teams in Turkey.

10

10

ALL REFERENCES

Leading Engineering Company

We are capable of designing, producing, integrating equipments, accomplishing turn-key projects, process analysis and optimization with the best engineering team in Turkey.

The Most Innovative

We have a strong R&D center that always welcomes sharp minds with fresh ideas. We have contributed to the technological advancement in every area that we are active.

Multidiciplinary Aproach

With our integrated technologies we are providing solutions on various areas; combining energy and agriculture, designing greenfield and brownfield projects, and digitalization.

ONGOING PROJECTS

LAST UPDATE 12/2025

Industrial Presence Around the World

Designing, engineering, and executing large-scale industrial solutions across continents, building facilities, automating systems, and driving economic transformation in every region we touch.

Updates on major investments, industrial advancements, and achievements across manufacturing, automation, and engineering.

Updates on major investments, industrial advancements, and achievements across manufacturing, automation, and engineering.

ALL NEWS

ALL NEWS

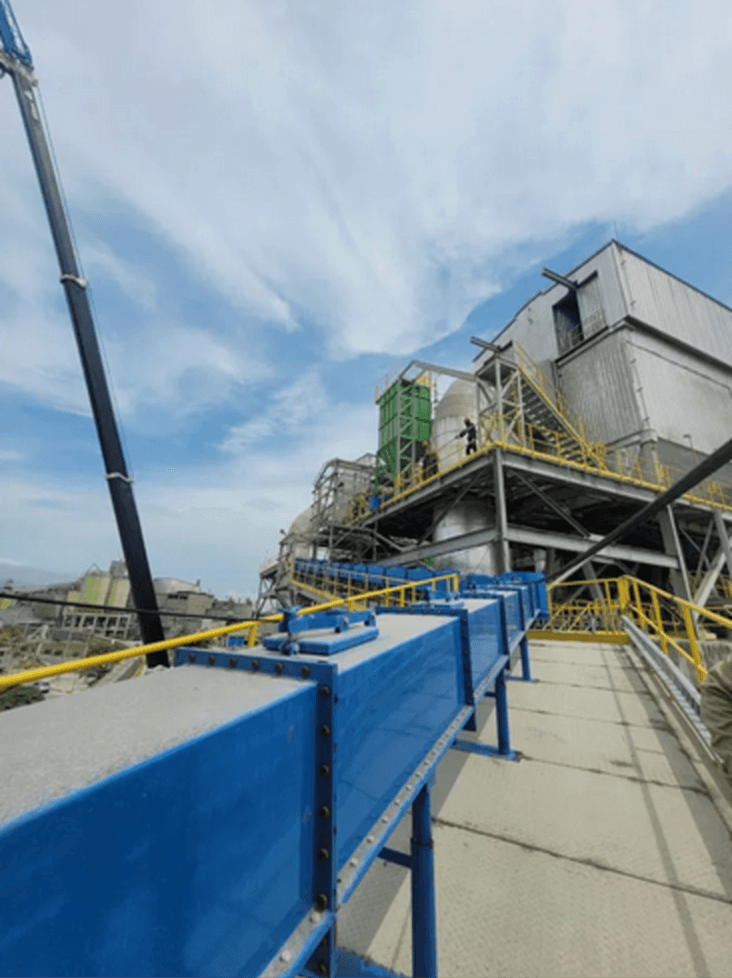

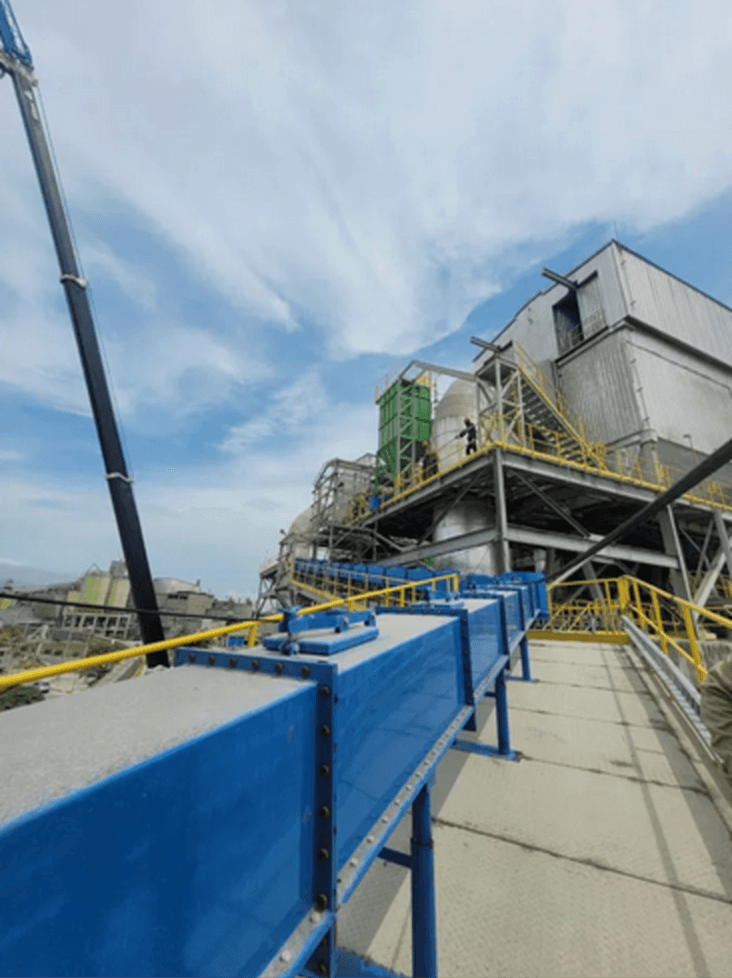

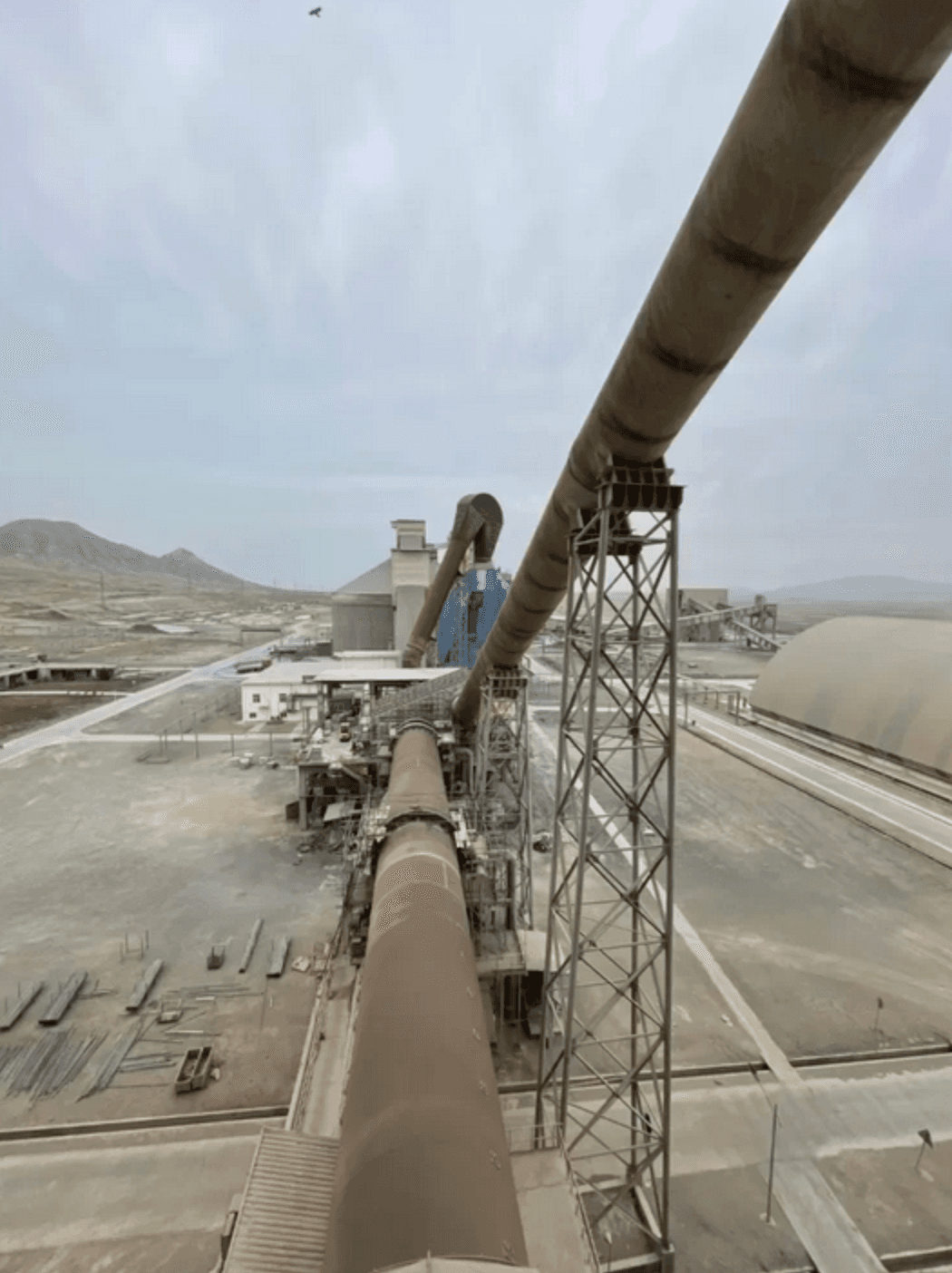

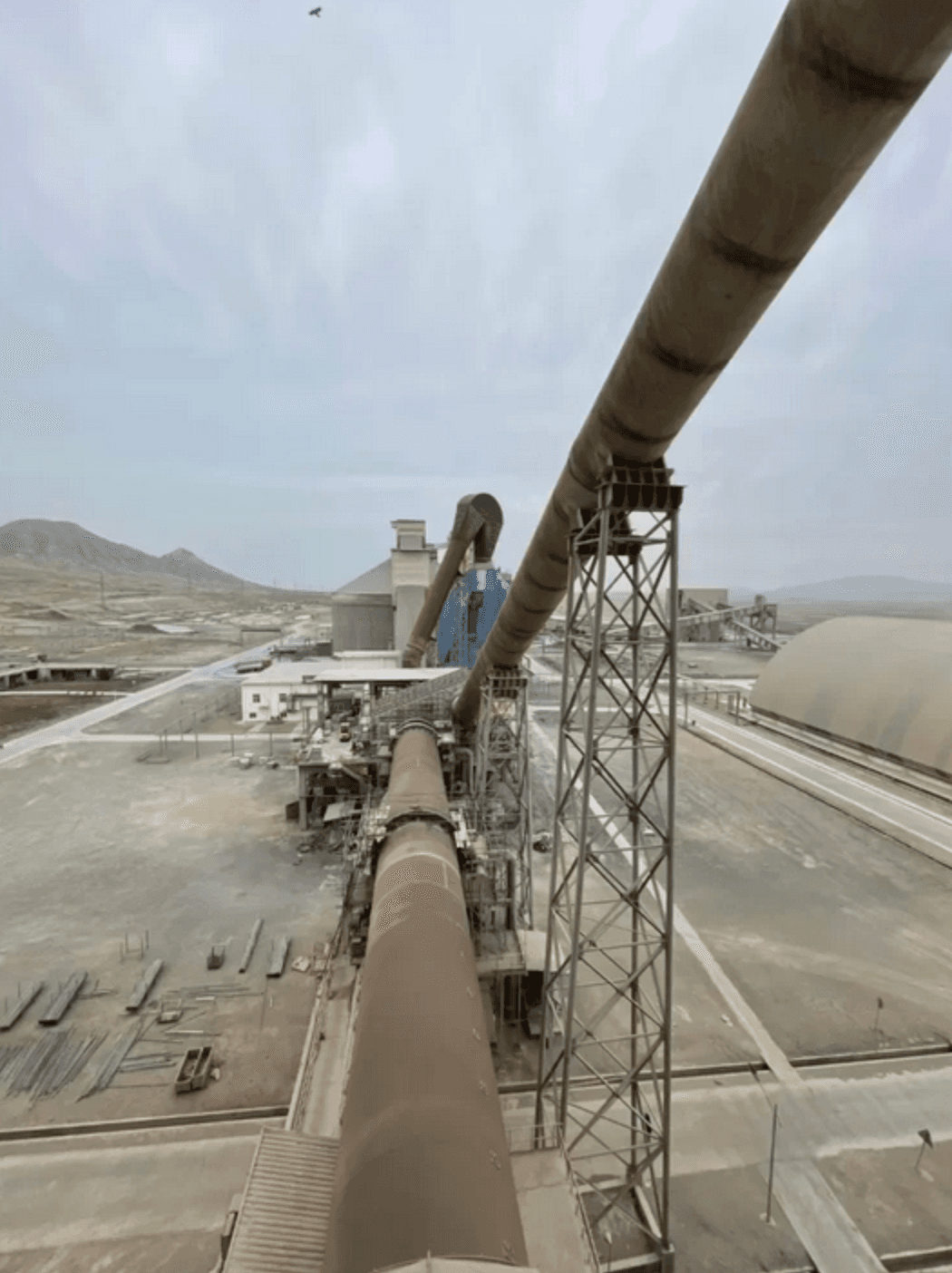

DAL completes modernization at Cementos Argos Cartagena plant

A major engineering and equipment modernization project has been successfully completed at the Cementos Argos plant in Cartagena, Colombia, marking an important milestone in the delivery of advanced solutions for the cement industry.

The project underscores a continued commitment to providing high-performance, reliable, and future-ready technologies to cement producers across Latin America and beyond. The scope of work included the supply and installation of precision-engineered airslides and diverter gates, high-efficiency airslide fans with optimized discharge systems, and a new bucket elevator featuring an advanced bag filtration system. Additional equipment delivered as part of the project comprised robust double-flap valves, screw conveyors, auxiliary mechanical systems, and industrial lifting solutions designed for long-term operational reliability.

The modernization was seamlessly integrated into the existing plant infrastructure, resulting in improved material handling efficiency and enhanced operational stability. Importantly, the upgrades were completed without disrupting ongoing production, while also strengthening the plant’s long-term process reliability and maintenance planning capabilities.

The successful execution of this project highlights DAL’s expertise in managing complex turnkey deliveries, covering the full lifecycle from engineering design and manufacturing to installation and commissioning. Appreciation was extended to Cementos Argos for their cooperation and trust throughout the project.

DAL completes modernization at Cementos Argos Cartagena plant

A major engineering and equipment modernization project has been successfully completed at the Cementos Argos plant in Cartagena, Colombia, marking an important milestone in the delivery of advanced solutions for the cement industry.

The project underscores a continued commitment to providing high-performance, reliable, and future-ready technologies to cement producers across Latin America and beyond. The scope of work included the supply and installation of precision-engineered airslides and diverter gates, high-efficiency airslide fans with optimized discharge systems, and a new bucket elevator featuring an advanced bag filtration system. Additional equipment delivered as part of the project comprised robust double-flap valves, screw conveyors, auxiliary mechanical systems, and industrial lifting solutions designed for long-term operational reliability.

The modernization was seamlessly integrated into the existing plant infrastructure, resulting in improved material handling efficiency and enhanced operational stability. Importantly, the upgrades were completed without disrupting ongoing production, while also strengthening the plant’s long-term process reliability and maintenance planning capabilities.

The successful execution of this project highlights DAL’s expertise in managing complex turnkey deliveries, covering the full lifecycle from engineering design and manufacturing to installation and commissioning. Appreciation was extended to Cementos Argos for their cooperation and trust throughout the project.

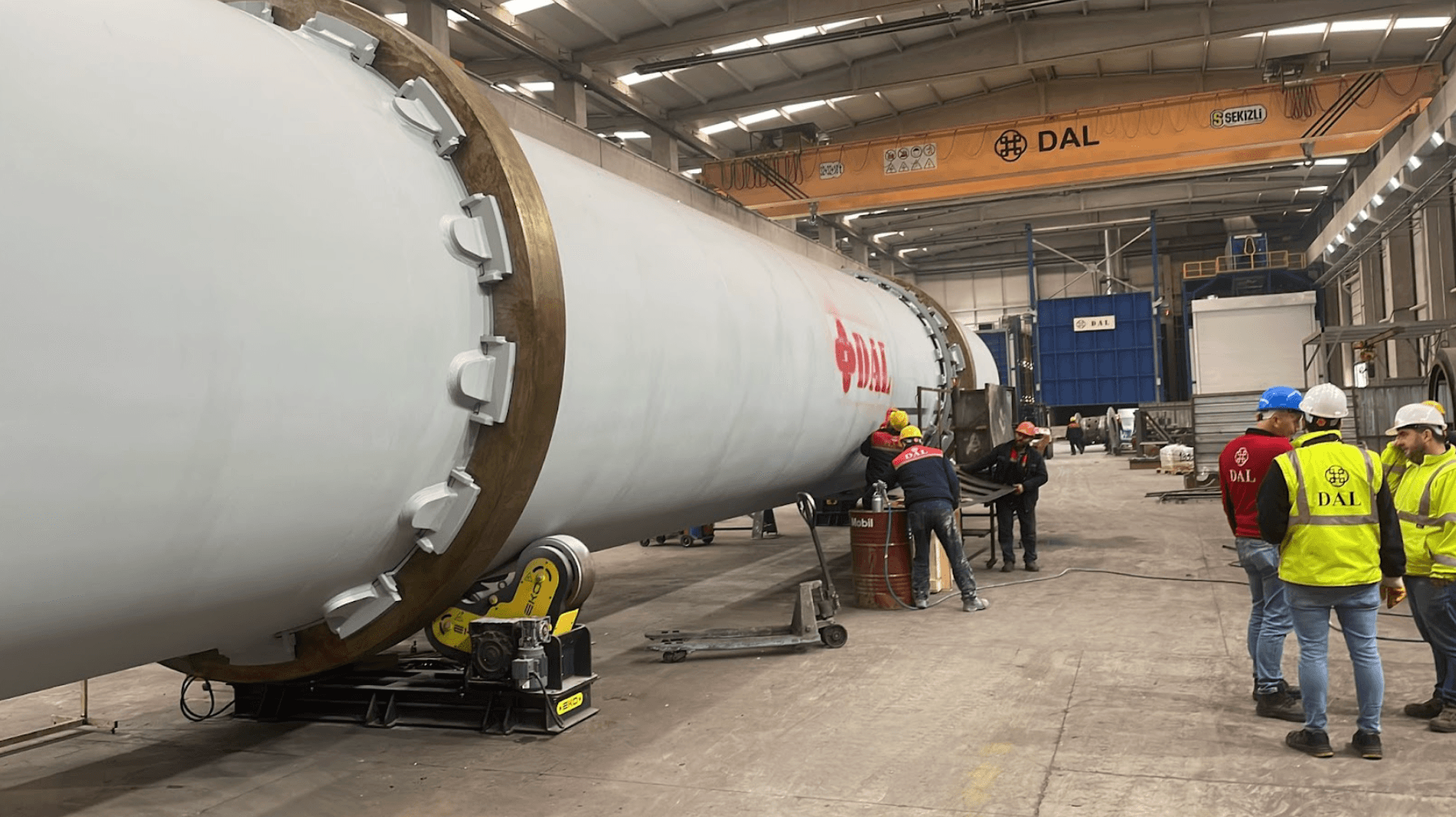

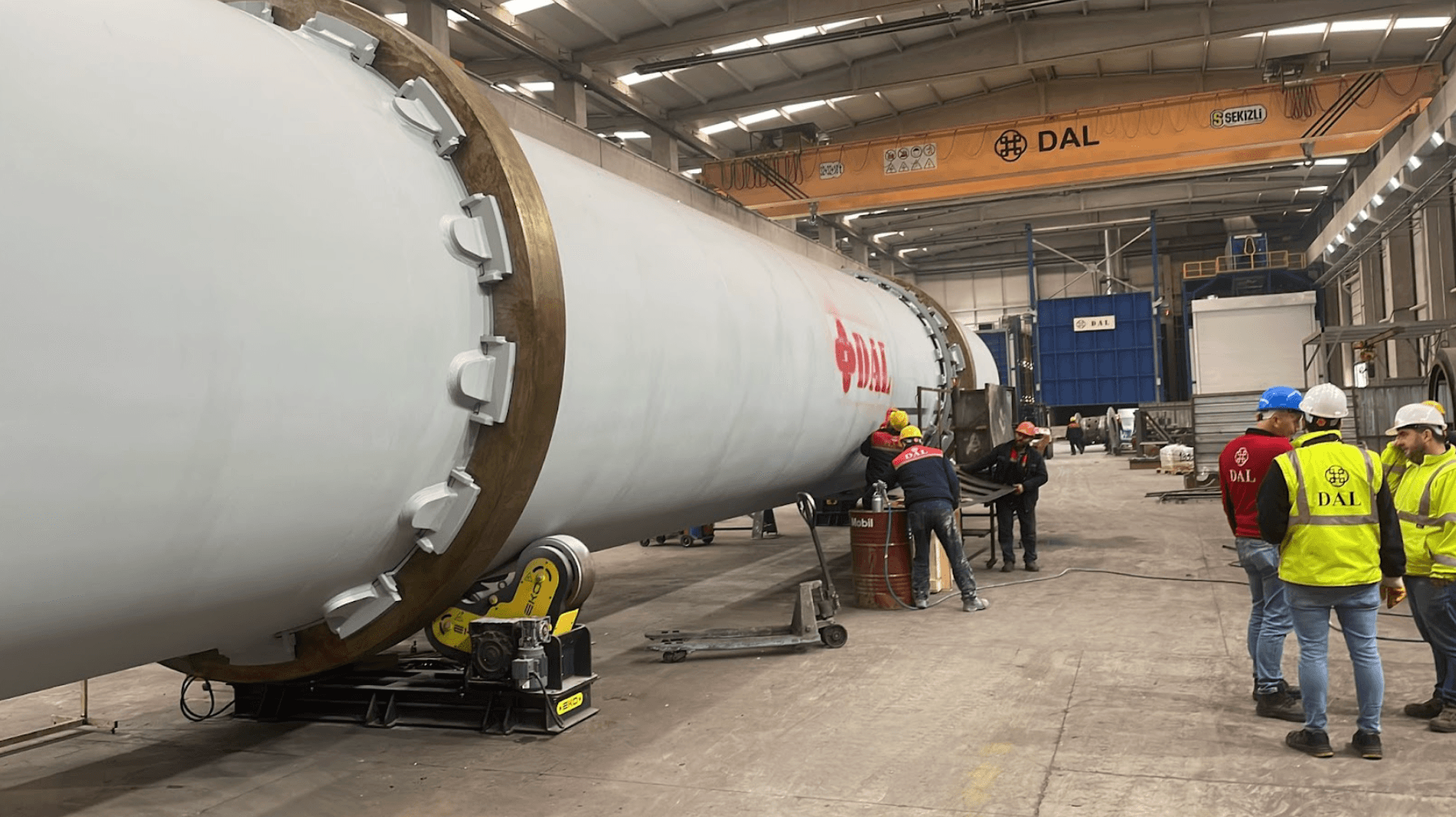

DAL and Fons Technology International update on recent orders

Dal Engineering and Fons Technology International in Turkey have completed a number of orders for the cement sector in recent months.

From the DAL workshop, a kiln shell Ø3.8m x 2.600m was successfully dispatched to Lukavac Cement doo in Bosnia and Herzegovina.

DAL Engineering Group has similarly delivered and installed a fully integrated rotary dryer, measuring Ø3m x 22m, at ZKW Otterbein’s cement and lime plant in Germany. This advanced equipment is designed to optimise production processes, improving both efficiency and sustainability within the cement and lime sectors.

Meanwhile, Fons Technology International, part of the DAL Engineering Group, has successfully delivered and commissioned a state-of-the-art clinker roller crusher with a capacity of 4000tpd for the Bouskoura plant (LafargeHolcim group) in Morocco.

DAL and Fons Technology International update on recent orders

Dal Engineering and Fons Technology International in Turkey have completed a number of orders for the cement sector in recent months.

From the DAL workshop, a kiln shell Ø3.8m x 2.600m was successfully dispatched to Lukavac Cement doo in Bosnia and Herzegovina.

DAL Engineering Group has similarly delivered and installed a fully integrated rotary dryer, measuring Ø3m x 22m, at ZKW Otterbein’s cement and lime plant in Germany. This advanced equipment is designed to optimise production processes, improving both efficiency and sustainability within the cement and lime sectors.

Meanwhile, Fons Technology International, part of the DAL Engineering Group, has successfully delivered and commissioned a state-of-the-art clinker roller crusher with a capacity of 4000tpd for the Bouskoura plant (LafargeHolcim group) in Morocco.

DAL wins multiple orders

DAL has reported the signing of a number of new orders in the cement sector in Colombia, Russia, Egypt and Qatar.

Dal Machinery & Design has been awarded the contract for delivering two surface feeders with a capacity of 2x200tph to Cementos Argos' Rio Claro cement plant in Colombia. According to the planned schedule, the installation of two surface feeders was executed in December 2018 and they are now fully operating. Dal Machinery & Design's surface feeders are part of Argos' calcined clays project in the municipality of Rio Claro, Antioquia. The same equipment was installed in the cement plant Studen Agrana in Bosnia-Herzegovina where a Dal Machinery & Design surface feeder had been operating for 10 years, designed for long-term use and without any maintenance.

Meanwhile, Dal Teknik Makina began converting a grey cement line to white cement production at the Zhigulyovsk Building Materials plant in Russia in November 2018. Dal Teknik Makina supplied engineering and procurement of certain equipment, including an upgrade to the kiln unit at the Zhigulyovsk Cement plant. Together with the unique raw material base of the plant, the converted cement works will meet the highest requirements for strength, quality and aesthetic characteristics of the white cement produced, claims Dal Teknik Makina.Furthermore, Heidelberg-owned Helwan Cement plant in Egypt approached Dal Teknik Makina in February 2019 to improve its process performance on clinker production Line No1. Dal Teknik Makina (DAL Engineering Group) has taken all required data to evaluate the existing situation during a three-day technical audit, carried out discussions with the plant staff and evaluated an audit report to optimise the Line 1 pyro-processing system. Dal Teknik Makina also offered solutions with particular focus on reducing specific heat consumption, increasing the plant's alternative fuel substitution rate, lowering energy consumption and raising kiln throughput.In addition, Dal Teknik Makina has been awarded a project to install a pilot-scale plant for calcium sulphoaluminate clinker production line in Qatar. Following a request from doctorate researchers from Gulf Organisation for Research & Development, Dal Teknik Makina engineers will evaluate the concept, identify potential operations issues and supply the complete engineering/instrumentation for the whole project.

DAL wins multiple orders

DAL has reported the signing of a number of new orders in the cement sector in Colombia, Russia, Egypt and Qatar.

Dal Machinery & Design has been awarded the contract for delivering two surface feeders with a capacity of 2x200tph to Cementos Argos' Rio Claro cement plant in Colombia. According to the planned schedule, the installation of two surface feeders was executed in December 2018 and they are now fully operating. Dal Machinery & Design's surface feeders are part of Argos' calcined clays project in the municipality of Rio Claro, Antioquia. The same equipment was installed in the cement plant Studen Agrana in Bosnia-Herzegovina where a Dal Machinery & Design surface feeder had been operating for 10 years, designed for long-term use and without any maintenance.

Meanwhile, Dal Teknik Makina began converting a grey cement line to white cement production at the Zhigulyovsk Building Materials plant in Russia in November 2018. Dal Teknik Makina supplied engineering and procurement of certain equipment, including an upgrade to the kiln unit at the Zhigulyovsk Cement plant. Together with the unique raw material base of the plant, the converted cement works will meet the highest requirements for strength, quality and aesthetic characteristics of the white cement produced, claims Dal Teknik Makina.Furthermore, Heidelberg-owned Helwan Cement plant in Egypt approached Dal Teknik Makina in February 2019 to improve its process performance on clinker production Line No1. Dal Teknik Makina (DAL Engineering Group) has taken all required data to evaluate the existing situation during a three-day technical audit, carried out discussions with the plant staff and evaluated an audit report to optimise the Line 1 pyro-processing system. Dal Teknik Makina also offered solutions with particular focus on reducing specific heat consumption, increasing the plant's alternative fuel substitution rate, lowering energy consumption and raising kiln throughput.In addition, Dal Teknik Makina has been awarded a project to install a pilot-scale plant for calcium sulphoaluminate clinker production line in Qatar. Following a request from doctorate researchers from Gulf Organisation for Research & Development, Dal Teknik Makina engineers will evaluate the concept, identify potential operations issues and supply the complete engineering/instrumentation for the whole project.

Dal Teknik Makina completes Nuh Çimento plant upgrade

Dal Teknik Makina has successfully carried out the modernisation of Kiln Line No1 at Nuh Çimento plant in Hereke, Turkey. Nuh Çimento plant has now increased its production capacity up to 3400tpd from 2800tpd, the specific heat consumption of clinker has been decreased to level of 740kcal/kg clinker from 870kcal/kg clinker and clinker temperature of 55˚C plus ambient temperature.

This project involved the design, manufacturing and erection of the preheater tower cyclones group, kiln feed transport system, clinker cooler, kiln hood, removing of dust cyclone at tertiary air duct, cooler vent fan modification, main bag filter duct modification and kiln inlet seal and commissioning of the system.

The first part of the upgrade project was the modification of the preheater tower, which as a result reduced the pressure drop, improved heat transfer and separation efficiency, and heat consumption.The second part of the project was the retrofit of the grate cooler. The clinker cooler, kiln hood, cooler fans and cooler vent fan were replaced by FONS Technology International. In this part, kiln hood, cooler vent, exit pipe of WHR and tertiary air duct were modified as well.

Finally, the horizontal duct of main bag filter inlet was replaced by an inclined one to avoid dust accumulation. The last step was the replacement of the pneumatic kiln feed by bucket elevator.After the execution of the upgrade project, which, by the way was carried out in a record time of 35 days from flame off to flame on, great values were achieved. Moreover, with this project Dal notably decreased electrical consumption by 7kWh/t. The raw mill capacity was increased from 160tph to 185tph. Dal’s most recent release at Nuh Çimento plant is part of Dal - Filter-to-filter pyroprocess concept which covers the following production units:

• Kiln/VRM dedusting unit

• Raw meal transport and homogenisation silo unit

• Kiln feed system

• Gas conditioning tower unit

• Preheater tower (cyclones, dip tubes, flap valves, etc)

• Precalciner

• RDF utilisation

• Rotary kiln (inlet & outlet seals, tyres & rollers, hydraulic thrust, etc)

• AD damper

• Clinker cooler

• Clinker cooler de-dusting unit (heat exchanger + bag filter or ESP).

Dal Teknik Makina completes Nuh Çimento plant upgrade

Dal Teknik Makina has successfully carried out the modernisation of Kiln Line No1 at Nuh Çimento plant in Hereke, Turkey. Nuh Çimento plant has now increased its production capacity up to 3400tpd from 2800tpd, the specific heat consumption of clinker has been decreased to level of 740kcal/kg clinker from 870kcal/kg clinker and clinker temperature of 55˚C plus ambient temperature.

This project involved the design, manufacturing and erection of the preheater tower cyclones group, kiln feed transport system, clinker cooler, kiln hood, removing of dust cyclone at tertiary air duct, cooler vent fan modification, main bag filter duct modification and kiln inlet seal and commissioning of the system.

The first part of the upgrade project was the modification of the preheater tower, which as a result reduced the pressure drop, improved heat transfer and separation efficiency, and heat consumption.The second part of the project was the retrofit of the grate cooler. The clinker cooler, kiln hood, cooler fans and cooler vent fan were replaced by FONS Technology International. In this part, kiln hood, cooler vent, exit pipe of WHR and tertiary air duct were modified as well.

Finally, the horizontal duct of main bag filter inlet was replaced by an inclined one to avoid dust accumulation. The last step was the replacement of the pneumatic kiln feed by bucket elevator.After the execution of the upgrade project, which, by the way was carried out in a record time of 35 days from flame off to flame on, great values were achieved. Moreover, with this project Dal notably decreased electrical consumption by 7kWh/t. The raw mill capacity was increased from 160tph to 185tph. Dal’s most recent release at Nuh Çimento plant is part of Dal - Filter-to-filter pyroprocess concept which covers the following production units:

• Kiln/VRM dedusting unit

• Raw meal transport and homogenisation silo unit

• Kiln feed system

• Gas conditioning tower unit

• Preheater tower (cyclones, dip tubes, flap valves, etc)

• Precalciner

• RDF utilisation

• Rotary kiln (inlet & outlet seals, tyres & rollers, hydraulic thrust, etc)

• AD damper

• Clinker cooler

• Clinker cooler de-dusting unit (heat exchanger + bag filter or ESP).

Two audits for mechanical and process to the Norm Cement Plant

Dal Teknik Makina has conducted two audits for mechanical and process point of view to the Norm Cement Plant to figure out the bottlenecks of the pyro line together with the cement grinding unit in order for the Norm Cement Plant to increase its production capacity and decrease the energy consumption. In addition to detailed production figures inspection, mechanical inspection has been conducted for both steel parts and mechanical equipment to figure out the reasons for corroded and weared out parts at the pyro line and two cement mills. Dal Teknik Makina has prepared a detailed report pointing out the required improvements the plant has to carry out in order to fulfill their capacity increase concerns.

Two audits for mechanical and process to the Norm Cement Plant

Dal Teknik Makina has conducted two audits for mechanical and process point of view to the Norm Cement Plant to figure out the bottlenecks of the pyro line together with the cement grinding unit in order for the Norm Cement Plant to increase its production capacity and decrease the energy consumption. In addition to detailed production figures inspection, mechanical inspection has been conducted for both steel parts and mechanical equipment to figure out the reasons for corroded and weared out parts at the pyro line and two cement mills. Dal Teknik Makina has prepared a detailed report pointing out the required improvements the plant has to carry out in order to fulfill their capacity increase concerns.

CIMSA Mersin Cement Plant modification

The goal of the project CIMSA Mersin Cement Plant wants to improve its 1st clinker production line by changing the 1st and 2nd stage cyclones for both two strings. Dal Teknik Makina offers “turnkey” replacement of cyclones. The modification project will allow electrical and a slight heat energy reduction by reducing pressure drop and improving separation efficiency of the cyclones.

The main equipment and design offered will be as follows:

• Modification of 1st and 2nd stage cyclones and riser ducts

• Downcomer ducts modification

• Dip tubes, pendulum flaps, meal pipes, splash boxes of the modified cyclones

• Accessories (manholes, poke holes,measuring points etc.)

• Dismantling and erection of the scope mentioned above

• Refractory procurement, demolishing and installation

CIMSA Mersin Cement Plant modification

The goal of the project CIMSA Mersin Cement Plant wants to improve its 1st clinker production line by changing the 1st and 2nd stage cyclones for both two strings. Dal Teknik Makina offers “turnkey” replacement of cyclones. The modification project will allow electrical and a slight heat energy reduction by reducing pressure drop and improving separation efficiency of the cyclones.

The main equipment and design offered will be as follows:

• Modification of 1st and 2nd stage cyclones and riser ducts

• Downcomer ducts modification

• Dip tubes, pendulum flaps, meal pipes, splash boxes of the modified cyclones

• Accessories (manholes, poke holes,measuring points etc.)

• Dismantling and erection of the scope mentioned above

• Refractory procurement, demolishing and installation

DAL has conducted a process audit for Isparta Cement Plant

Dal Teknik Makina has conducted a process audit for both clinker production lines of Isparta Cement Plant to figure out the bottlenecks of the pyro line in order for Isparta Cement Plant to burn alternative fuels without decreasing its production capacity. Technical inspection covered clinker production line measurements together with the ball type raw mill mechanical inspection for the 1st kiln line. After evaluating the current situation of the plant, together with the measurement results and documents given by the plant, Dal Teknik Makina has prepared a detailed report pointing out the needed improvements the plant has to carry out in order for them to burn alternative fuel and fuel injection points, which was the main concern of the plant.

DAL has conducted a process audit for Isparta Cement Plant

Dal Teknik Makina has conducted a process audit for both clinker production lines of Isparta Cement Plant to figure out the bottlenecks of the pyro line in order for Isparta Cement Plant to burn alternative fuels without decreasing its production capacity. Technical inspection covered clinker production line measurements together with the ball type raw mill mechanical inspection for the 1st kiln line. After evaluating the current situation of the plant, together with the measurement results and documents given by the plant, Dal Teknik Makina has prepared a detailed report pointing out the needed improvements the plant has to carry out in order for them to burn alternative fuel and fuel injection points, which was the main concern of the plant.

DAL representatives met with Uzbek statesmen

Chairman of DAL, Mr. DAL, together with Senior Directors Mr. Adnan CAN and Mr. Demircan KÖSE, held a high level meeting with the Deputy Prime Minister and Minister of Investment and Foreign Trade of Uzbekistan, Mr. S. Umurzakov.

The meeting was also attended by Deputy Minister Mr. L. Kudratov and the Ambassador of Uzbekistan to Turkey, Mr. A. Azamhocayev. The discussion focused on ongoing activities of DAL within Uzbekistan, where the company continues to advance industrial execution spanning automation, engineering, heavy manufacturing, and turnkey solutions.

Both sides reviewed the progress of current projects and explored new areas for collaboration that support Uzbekistan’s national industrial development goals. Uzbek officials expressed their full support for deeper cooperation, and DAL reaffirmed its commitment to expanding its presence and contributing to economic development through strategic investments and long term partnerships.

DAL representatives met with Uzbek statesmen

Chairman of DAL, Mr. DAL, together with Senior Directors Mr. Adnan CAN and Mr. Demircan KÖSE, held a high level meeting with the Deputy Prime Minister and Minister of Investment and Foreign Trade of Uzbekistan, Mr. S. Umurzakov.

The meeting was also attended by Deputy Minister Mr. L. Kudratov and the Ambassador of Uzbekistan to Turkey, Mr. A. Azamhocayev. The discussion focused on ongoing activities of DAL within Uzbekistan, where the company continues to advance industrial execution spanning automation, engineering, heavy manufacturing, and turnkey solutions.

Both sides reviewed the progress of current projects and explored new areas for collaboration that support Uzbekistan’s national industrial development goals. Uzbek officials expressed their full support for deeper cooperation, and DAL reaffirmed its commitment to expanding its presence and contributing to economic development through strategic investments and long term partnerships.

DAL completes cyclone project at Mersin Cement

Dal Teknik Makina has completed a turnkey project for the replacement of cyclones and riser ducts at ÇİMSA’s Mersin cement plant in Turkey.

The project covered the first and second-stage cyclone modification and their riser ducts, plus modification of the downcomer ducts, dip tubes, pendulum flaps, meal pipes and splash boxes of the modified parts.The order also included the provision of accessories (manholes, poking holes, measuring points, etc) of the modified parts, the dismantling and erection of the project scope and refractory procurement, demolishing and installation.The project was completed successfully within eight months, reports Dal Engineering.

DAL completes cyclone project at Mersin Cement

Dal Teknik Makina has completed a turnkey project for the replacement of cyclones and riser ducts at ÇİMSA’s Mersin cement plant in Turkey.

The project covered the first and second-stage cyclone modification and their riser ducts, plus modification of the downcomer ducts, dip tubes, pendulum flaps, meal pipes and splash boxes of the modified parts.The order also included the provision of accessories (manholes, poking holes, measuring points, etc) of the modified parts, the dismantling and erection of the project scope and refractory procurement, demolishing and installation.The project was completed successfully within eight months, reports Dal Engineering.

DAL attended Turkey-Kazakhstan Business Forum

Along with many important political and business figures, Turkey's vice president Mr. Fuat Oktay, and Kazakh Prime Minister Mr. Askar Mamin also have attended the Event.

During the Event, recent developments in Kazakh Economy, business opportunities and governement incentives for investments are discussed. Necessary steps to be taken to improve cooperation in commercial and economic relations was another topic.

Mr. Demircan Köse, the CFO and Advisory Board Member of DAL has shared his experiences and ideas as a speaker in the Forum under the session «New Opportunities: Industries, fields of Businesses and Projects». He emphasized that the cultural and historical ties created an immense opportunity to work and grow together in trade and business. He also invited all Turkish businessmen to take the opportunities that the Kazakh Officials provides for investors.

DAL attended Turkey-Kazakhstan Business Forum

Along with many important political and business figures, Turkey's vice president Mr. Fuat Oktay, and Kazakh Prime Minister Mr. Askar Mamin also have attended the Event.

During the Event, recent developments in Kazakh Economy, business opportunities and governement incentives for investments are discussed. Necessary steps to be taken to improve cooperation in commercial and economic relations was another topic.

Mr. Demircan Köse, the CFO and Advisory Board Member of DAL has shared his experiences and ideas as a speaker in the Forum under the session «New Opportunities: Industries, fields of Businesses and Projects». He emphasized that the cultural and historical ties created an immense opportunity to work and grow together in trade and business. He also invited all Turkish businessmen to take the opportunities that the Kazakh Officials provides for investors.

Global Engineering Presence

Our capabilities span cement plants, mining operations, renewable energy systems and heavy industry facilities, placing us among the world’s leading EPC contractors and equipment suppliers.

Technology, Innovation & Turn-Key Delivery

Equipped with a strong R&D foundation and industry-leading Turkish engineering talent, we integrate machinery, automation systems, energy-efficient technology and streamlined workflow optimization.

CONTACT US

CONTACT US

YEAR 1985

One of the R&D Center

Imported motor and actuators of foreseen lack of these equipments in all sectors of Turkey.

YEAR 1985

One of the R&D Center

Imported motor and actuators of foreseen lack of these equipments in all sectors of Turkey.

YEAR 1990

Representative of WEG

Turnkey solutions in cement, lime, mining, mineral resources and Electric Automation

YEAR 1990

Representative of WEG

Turnkey solutions in cement, lime, mining, mineral resources and Electric Automation

YEAR 1995

1st Automation Company

Turkish heavy industry Solution Partner with Siemens, A&D Business Partner with Siemens, ABB, Schneider.

YEAR 1995

1st Automation Company

Turkish heavy industry Solution Partner with Siemens, A&D Business Partner with Siemens, ABB, Schneider.

YEAR 2004

100% Turkish Engineering

Dal Teknik 1st Turkish company to be involved with the turnkey basis contracting solutions.

YEAR 2004

100% Turkish Engineering

Dal Teknik 1st Turkish company to be involved with the turnkey basis contracting solutions.

YEAR 2012

Jizzakh Cement Plant

Completed in March 2014 with 100% Turkish engineering by Dal Teknik.

YEAR 2012

Jizzakh Cement Plant

Completed in March 2014 with 100% Turkish engineering by Dal Teknik.

YEAR 2016

Surhanderya Cement Plant

A greenfield and EPC basis cement plant project was contracted in Uzbekistan.

YEAR 2016

Surhanderya Cement Plant

A greenfield and EPC basis cement plant project was contracted in Uzbekistan.

YEAR 2017

Tailor-made Machine Design

A new ground from DMT, Clinker crusher with the capacity of 12,000 tpd.

YEAR 2017

Tailor-made Machine Design

A new ground from DMT, Clinker crusher with the capacity of 12,000 tpd.

YEAR 2018

Corlu Heavy Machinery

In order to enhance its capabilities DAL constructed a workshop for heavy machinery and equipment.

YEAR 2018

Corlu Heavy Machinery

In order to enhance its capabilities DAL constructed a workshop for heavy machinery and equipment.

YEAR 2018

Zomin Cement

Dal Teknik acquired and refurbished a cement & lime plant in Uzbekistan.

YEAR 2018

Zomin Cement

Dal Teknik acquired and refurbished a cement & lime plant in Uzbekistan.

YEAR 2019

Surhanderya Cement Plant

Surhanderya Cement Plant comissioned in record-breaking shortest time.

YEAR 2019

Surhanderya Cement Plant

Surhanderya Cement Plant comissioned in record-breaking shortest time.

YEAR 2019

Dal Heavy Industries

DAL constructed a high-tech steel constructon plant in Uzbekistan.

YEAR 2019

Dal Heavy Industries

DAL constructed a high-tech steel constructon plant in Uzbekistan.

YEAR 2022

Filter-to-filter Pyroprocess

Dal Teknik completes Nuh Çimento plant upgrade, showcasing the concept.

YEAR 2022

Filter-to-filter Pyroprocess

Dal Teknik completes Nuh Çimento plant upgrade, showcasing the concept.

YEAR 2024

DAL Wins Global Orders

A number of new orders in Colombia, Russia, Egypt and Qatar.

YEAR 2024

DAL Wins Global Orders

A number of new orders in Colombia, Russia, Egypt and Qatar.

YEAR 2025

Columbia Turnkey Delivery

DAL completes modernisation at Cementos Argos Cartagena plant.

YEAR 2025

Columbia Turnkey Delivery

DAL completes modernisation at Cementos Argos Cartagena plant.

With our integrated technologies we are providing solutions on various areas; combining energy and agriculture.

With our integrated technologies we are providing solutions on various areas; combining energy and agriculture.

SEE LOCATIONS

SEE LOCATIONS

Dal Heavy Industries

EST. 2018

Located at 100 km south of Tashkent, Angren Free Economic Zone, Dal Heavy Industries Co. has a modern Plant constructed over 13 hectares area and has been commissioned in summer 2018.

The current capacity is 12.000 tonnes per year and gradually will increase to 24.000 tpy in the second phase and to 30.000 tpy in the third phase.

Dal Heavy Industries is the most important metal construction company in the region since it’s products fully complies with international standards such as ISO 3834-2.

VISIT DAL HEAVY INDUSTRIES

Fons Technology International

EST. 2010

Fons Technology International produces clinker coolers with high productivity to the world cement market.

The headquarters is in Istanbul, Turkey and there are offices in Denmark, India and Czech Republic and representative offices in Brazil and Jordan.

Fons is the first company in the world, which applied for patent in the technology of horizontal clinker cooler.

VISIT FONS TECHNOLOGY

Dal Electric Automation Co.

EST. 1995

Dal Electric Automation Co. is in the business to serve for Turkish heavy industry since 1995.

The Company is a turnkey contractor of;

High and medium voltage transformer centers and distribution networks

Low voltage distribution networks

Illumination systems

Process control systems

Building automation systems

Cabling including grounding of electricity and automation systems

Dal Electric Automation Co. is a solution partner of Siemens, and business partners with ABB, Schneider and Eaton.

VISIT DAL ELECTRIC AUTOMATION

Dal Teknik

EST. 1985

Dal Teknik, the flagship of the Holding, was established in 1985 and has been carrying out domestic and international projects on a turnkey basis with 100% Turkish Engineering since then.

In 1998, the company expanded its capabilities by absorbing Dal Machinery & Design Co., integrating advanced technology solutions into its operations.

With a total annual production capacity of 8.5 million tons in commissioned cement industry projects, Dal Teknik leads the domestic market as the first and only company with 100% Turkish engineering.

The company remains robust in the international market, competing with European Technology companies and Chinese EPC contractors, and securing its place in the top ten league of the industry.

VISIT DAL TEKNIK

Dal Electric Motors Co.

EST. 1990

DAL Electric Motors Co. was established in 1990.

The company focuses on tailor-made solutions to the cement, lime, mining, mineral resources, electricity and automation industry and provides technical service support.

Dal Electric Motors is among the leading five companies in the industry world-wide, producing motors meeting the NEMA (The National Electrical Manufacturers Association of U.S.) standards.

The company is the distributor for well known brands such as WEG, Falk Rexnord and ISGEV.

VISIT DAL ELECTRIC MOTORS

Dal Solar

EST. 2017

DAL SOLAR was established in 2017 under the umbrella of DAL Holding, a company that has been providing turnkey services in the Cement, Energy, Machinery Manufacturing, and Electric Motor sectors for 35 years . Its purpose is to offer turnkey Solar Power Plant (EPC) installation, maintenance and repair services, and site analysis and reporting services, starting from the application process.

In 2017, along with R&D studies on Lithium Battery Groups and Home Systems, the company began installing turnkey solar power plants in many regions, helping investors benefit from credit and grant support programs for Energy Cooperative Projects and Agricultural Irrigation Projects. Since 2018, in addition to ground-mounted solar power projects, it has been offering turnkey services for rooftop projects on factories, farms, and other locations.

VISIT DAL SOLAR

Dal Heavy Industries

EST. 2018

Located at 100 km south of Tashkent, Angren Free Economic Zone, Dal Heavy Industries Co. has a modern Plant constructed over 13 hectares area and has been commissioned in summer 2018.

The current capacity is 12.000 tonnes per year and gradually will increase to 24.000 tpy in the second phase and to 30.000 tpy in the third phase.

Dal Heavy Industries is the most important metal construction company in the region since it’s products fully complies with international standards such as ISO 3834-2.

VISIT DAL HEAVY INDUSTRIES

Fons Technology International

EST. 2010

Fons Technology International produces clinker coolers with high productivity to the world cement market.

The headquarters is in Istanbul, Turkey and there are offices in Denmark, India and Czech Republic and representative offices in Brazil and Jordan.

Fons is the first company in the world, which applied for patent in the technology of horizontal clinker cooler.

VISIT FONS TECHNOLOGY

Dal Electric Automation Co.

EST. 1995

Dal Electric Automation Co. is in the business to serve for Turkish heavy industry since 1995.

The Company is a turnkey contractor of;

High and medium voltage transformer centers and distribution networks

Low voltage distribution networks

Illumination systems

Process control systems

Building automation systems

Cabling including grounding of electricity and automation systems

Dal Electric Automation Co. is a solution partner of Siemens, and business partners with ABB, Schneider and Eaton.

VISIT DAL ELECTRIC AUTOMATION

Dal Teknik

EST. 1985

Dal Teknik, the flagship of the Holding, was established in 1985 and has been carrying out domestic and international projects on a turnkey basis with 100% Turkish Engineering since then.

In 1998, the company expanded its capabilities by absorbing Dal Machinery & Design Co., integrating advanced technology solutions into its operations.

With a total annual production capacity of 8.5 million tons in commissioned cement industry projects, Dal Teknik leads the domestic market as the first and only company with 100% Turkish engineering.

The company remains robust in the international market, competing with European Technology companies and Chinese EPC contractors, and securing its place in the top ten league of the industry.

VISIT DAL TEKNIK

Dal Electric Motors Co.

EST. 1990

DAL Electric Motors Co. was established in 1990.

The company focuses on tailor-made solutions to the cement, lime, mining, mineral resources, electricity and automation industry and provides technical service support.

Dal Electric Motors is among the leading five companies in the industry world-wide, producing motors meeting the NEMA (The National Electrical Manufacturers Association of U.S.) standards.

The company is the distributor for well known brands such as WEG, Falk Rexnord and ISGEV.

VISIT DAL ELECTRIC MOTORS

Dal Solar

EST. 2017

DAL SOLAR was established in 2017 under the umbrella of DAL Holding, a company that has been providing turnkey services in the Cement, Energy, Machinery Manufacturing, and Electric Motor sectors for 35 years . Its purpose is to offer turnkey Solar Power Plant (EPC) installation, maintenance and repair services, and site analysis and reporting services, starting from the application process.

In 2017, along with R&D studies on Lithium Battery Groups and Home Systems, the company began installing turnkey solar power plants in many regions, helping investors benefit from credit and grant support programs for Energy Cooperative Projects and Agricultural Irrigation Projects. Since 2018, in addition to ground-mounted solar power projects, it has been offering turnkey services for rooftop projects on factories, farms, and other locations.

VISIT DAL SOLAR

MANUFACTURING

CORLU/TURKEY

100% Turkish Manufacturing

Designing, engineering, and executing large-scale industrial solutions across continents, building facilities, automating systems, and driving economic transformation in every region we touch.

MANUFACTURING PRESENTATION

MANUFACTURING PRESENTATION

Location: Corlu / ASB European Free Zone / Türkgücü

Our workshops are located in one of the biggest and modern industry parks of Turkey called European Free Zone and as well as in Industrial area of Türkgücü.

EFZ, founded on a land of 2 million square meters in Corlu/Tekirdag which is located in the center of Istanbul, close to Europe and major transportion networks.

The production of the world's leading brands takes place in this zone.

Location: Corlu / ASB European Free Zone / Türkgücü

Our workshops are located in one of the biggest and modern industry parks of Turkey called European Free Zone and as well as in Industrial area of Türkgücü.

EFZ, founded on a land of 2 million square meters in Corlu/Tekirdag which is located in the center of Istanbul, close to Europe and major transportion networks.

The production of the world's leading brands takes place in this zone.

Location: Corlu / ASB European Free Zone / Türkgücü

Our workshops are located in one of the biggest and modern industry parks of Turkey called European Free Zone and as well as in Industrial area of Türkgücü.

EFZ, founded on a land of 2 million square meters in Corlu/Tekirdag which is located in the center of Istanbul, close to Europe and major transportion networks.

The production of the world's leading brands takes place in this zone.

Well designed modular manufacturing workshop, equipped with an easy access to loading docks for trucks, raised flow levers and clear open space.

Each unit has its own dedicated loading yard with ram access for forklifts and has an ample on site parking.

Specifications | EFZ | Türkgücü |

|---|---|---|

Indoor area | 10.000 m2 (each building 5.000 m2) | 6.000 m2 |

Surrounding area | 25.000 m2 | 9.000 m2 |

Height under the crane | 10,5 m | 10 m |

Management building | 3 stages 500 m2 | 400 m2 |

Well designed modular manufacturing workshop, equipped with an easy access to loading docks for trucks, raised flow levers and clear open space.

Each unit has its own dedicated loading yard with ram access for forklifts and has an ample on site parking.

Specifications | EFZ | Türkgücü |

|---|---|---|

Indoor area | 10.000 m2 (each building 5.000 m2) | 6.000 m2 |

Surrounding area | 25.000 m2 | 9.000 m2 |

Height under the crane | 10,5 m | 10 m |

Management building | 3 stages 500 m2 | 400 m2 |

Well designed modular manufacturing workshop, equipped with an easy access to loading docks for trucks, raised flow levers and clear open space.

Each unit has its own dedicated loading yard with ram access for forklifts and has an ample on site parking.

Specifications | EFZ | Türkgücü |

|---|---|---|

Indoor area | 10.000 m2 (each building 5.000 m2) | 6.000 m2 |

Surrounding area | 25.000 m2 | 9.000 m2 |

Height under the crane | 10,5 m | 10 m |

Management building | 3 stages 500 m2 | 400 m2 |

Our presence in the European Free Trade Zone brings DEG close to our markets in Central & Eastern Europe, the Middle-East and North Africa.

Manufacturing companies staying within free zone, custom related taxes and regulations are not applicable. Such as; Value Added, Tax Customs, Duties, RUSF Tax(6%).

Total area | 2.000.000 m2 |

Establishment year | 1999 |

Company number | 150 |

Trade volume | $2.4 bn |

Our presence in the European Free Trade Zone brings DEG close to our markets in Central & Eastern Europe, the Middle-East and North Africa.

Manufacturing companies staying within free zone, custom related taxes and regulations are not applicable. Such as; Value Added, Tax Customs, Duties, RUSF Tax(6%).

Total area | 2.000.000 m2 |

Establishment year | 1999 |

Company number | 150 |

Trade volume | $2.4 bn |

Our presence in the European Free Trade Zone brings DEG close to our markets in Central & Eastern Europe, the Middle-East and North Africa.

Manufacturing companies staying within free zone, custom related taxes and regulations are not applicable. Such as; Value Added, Tax Customs, Duties, RUSF Tax(6%).

Total area | 2.000.000 m2 |

Establishment year | 1999 |

Company number | 150 |

Trade volume | $2.4 bn |

PRODUCTS AND SERVICES PRESENTATION

PRODUCTS AND SERVICES PRESENTATION

HEAVY MACHINERY

HEAVY MACHINERY

HEAVY MACHINERY

TURNKEY PLANTS

TURNKEY PLANTS

TURNKEY PLANTS

PRECISE MANUFACTURING

PYRO PROCESS DESIGN

PYRO PROCESS DESIGN

PYRO PROCESS DESIGN

PROCESS AUDITS

PROCESS AUDITS

PROCESS AUDITS

“It’s not about ideas. It’s about making ideas happen.”

UP TO 2000 EMPLOYEES

One of the leading players in the industry with skilled and open-minded employees.

UP TO 2000 EMPLOYEES

One of the leading players in the industry with skilled and open-minded employees.

EQUIPMENT SUPPLY

Among the leading 5 critical equipment supplier groups in the industry.

EQUIPMENT SUPPLY

Among the leading 5 critical equipment supplier groups in the industry.

GLOBAL VENTURES

One of the leading players in the industry with skilled and open-minded employees.

GLOBAL VENTURES

One of the leading players in the industry with skilled and open-minded employees.

GLOBAL VENTURES

One of the leading players in the industry with skilled and open-minded employees.

EPC TURNKEY

Among the top 10 in EPC turnkey solutions globally.

EPC TURNKEY

Among the top 10 in EPC turnkey solutions globally.

FROM STATES TO JAPAN

Providing technologies all over the world for 50+ years.

FROM STATES TO JAPAN

Providing technologies all over the world for 50+ years.

FROM STATES TO JAPAN

Providing technologies all over the world for 50+ years.

AT YOUR SERVICE

Active in cement, construction, energy, chemicals, mineral resource industries.

AT YOUR SERVICE

Active in cement, construction, energy, chemicals, mineral resource industries.

AT YOUR SERVICE

Active in cement, construction, energy, chemicals, mineral resource industries.